More Info

| CHARACTERISTICS | SPECIFICATIONS |

| Design Standard | API 602, API 600, MESC SPE 77 / 101, MESC SPE 77 / 102, ASME B16.34 |

| Pressure / Temperature Rating | ASME B 16.34 |

| Test (Inspection) Standard | API 598, API 6D, MESC SPE 77/101, 77/ 102, ISO 5208, API6FA, ISO 10497, ISO 15848 – 1&2, Bs6364 |

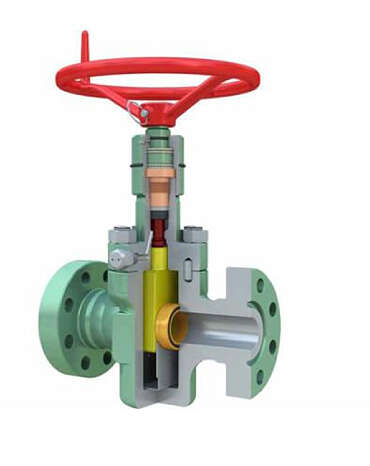

| Construction Details | Bolted Bonnet / Pressure Seal Bonnet, OS & Y Type Rising Stem |

| End connection | Screwed, Socket Weld, Flanged, Hub End, Butt-Weld |

| Operator / Actuator |

Lever, Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised) Gate Valves are available in six different types :

|